How to choose the right System-on-Module?

System-on-Modules (SOMs) are fully featured, miniature board computers designed for integration into custom industrial applications. System-on-Modules allow to speed-up time to market, save development cost and reduce design complexity.

When you select a System-on-Module to integrate into your design, it becomes a critical component that will affect not just your product development, but also its manufacturing throughout the entire lifecycle. There are many important factors to consider, both for choosing a specific SOM model and when selecting the SOM vendor.

Selecting the System-on-Module

System-on-Chip

There are a lot of different System-on-Chips (SoCs) on the market. Many might look great on paper, but lack the vendor support necessary for industrial projects.

It is advisable to avoid exotic solutions and use a SOM based on a “mainstream” general-purpose SoC from a vendor with established track record in the embedded industrial market.

Long-Term Availability

Long-term availability is absolutely crucial for most industrial projects. In some applications where design and certification cycles are very long, it can take 3 to 5 years for a product to begin mass production. In other cases, companies might need to re-use the same design in several different projects.

It is highly recommended to choose a SOM which has at least 10 years of guaranteed availability from the beginning of your project.

Software Packages

Board support packages for boot-loader and operating system are an integral part of any System on Module.

Verify that the SOM is provided with full BSP for the O/S you plan to use. It is also recommended to review the supporting documentation.

Connectivity

Not all System on Modules expose all SoC signals. Furthermore, most ARM SoCs use signal multiplexing, which imposes limitations on the set of functions you can use simultaneously.

Ensure that the required signals are in fact available in the SOM you choose and that there are no collisions between the functions.

Configurability

Some System on Module are offered with configurable options such as different RAM and storage capacities and optional peripherals. This approach allows customers to select the exact features needed for their application and optimize SOM cost.

Check whether the SOM you choose supports configurable options. Inquire which configurations are actually available and what is the vendor’s policy for producing the configuration you would need for your project.

Form-Factor and Connection Type

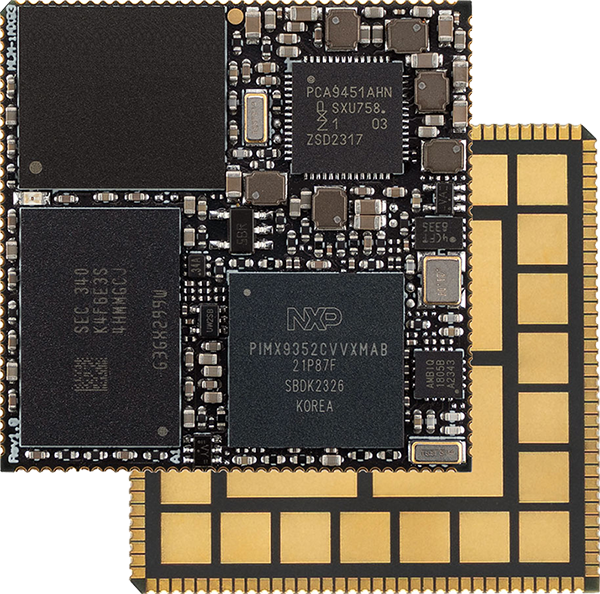

There are three main types of System on Module form-factors – edge connector SOMs, mezzanine connector SOMs and solder-down SOMs.

- Edge connector SOMs are very common. The main downside of these boards is inherently larger foot-print, due to the constraints of the edge connector length. Also, keep in mind that the body of the mating connector takes up board space – in addition to the size of the SOM itself.

- Mezzanine connector SOMs usually allow more efficient board space utilization with no apparent drawbacks.

- Solder-down SOMs offer several unique advantages such as enhanced mechanical robustness, reduced height profile and automated assembly. For additional information refer to Advantages of solder-down System-on-Modules.

| Edge Connector | Mezzanine Connectors | SMD Solder-Down | |

|---|---|---|---|

|  |  |  |

Power Consumption and Heat Dissipation

Verify that the selected SOM fits within the power budget of your system. SOM power consumption significantly depends on the specific use case and processing load. Reputable SOM vendors normally provide detailed power consumption data for different typical use cases.

Consider whether the SOM in your design will require a heat-dissipation solution. Check whether the SOM is provided with a heat-plate or heat-sink.

Selecting the SOM vendor

Selecting the right vendor is of no less importance than choosing the board. Invest some time and effort into ensuring that you choose a reliable, well-established manufacturer with a proven track record and presence in the embedded industrial space.

Vendor Reliability

Consider the following aspects to determine vendor expertise and reliability:

- How many years has this company been working with the embedded market?

- How many SOM products does this vendor manufacture?

- Are System-on-Modules part of the vendor’s core business?

Longevity Commitment

Check whether the SOM vendor provides a formal long-term availability commitment.

Inquire whether the vendor has established policies and programs to support that commitment.

In-house Manufacturing

SOM vendors that depend on external manufacturing partners are inherently exposed to additional risk factors. Having full control of the entire production cycle is extremely important for sustained production quality and uninterrupted supply.

It is strongly recommended to choose a vendor with in-house manufacturing.

Design Documentation

- Take some time to review the SOM documentation: datasheet, detailed reference guide, drawings etc.

- Check the set of carrier-board design resources provided by the SOM vendor – schematics, bill of materials, PCB layout, 3D models etc.

- Make sure that you get pre-validated reference building blocks that you will need for your project

Technical Support

Using a SOM in your project involves rather complicated hardware and software integration. In most cases you will need the vendor’s assistance during your design or bring-up process. It is highly recommended to ensure the vendor you select will provide you with professional and helpful support:

- How is technical support provided? Does the vendor use a dedicated support portal?

- Is the support free or will you be required to pay for it?

- Can you get direct access to the vendor’s design engineers?

- Does the vendor offer schematics design review?

Certification Support

Most likely your product will need to be certified for FCC, CE and other regulatory standards. Your carrier board and the SOM you select will need to pass EMC and safety testing. If the SOM includes on-board WiFi or Bluetooth, verify that the SOM vendor uses a pre-certified solution and can provide the necessary certification support.